Tools

Find a replacement for your outdated pump

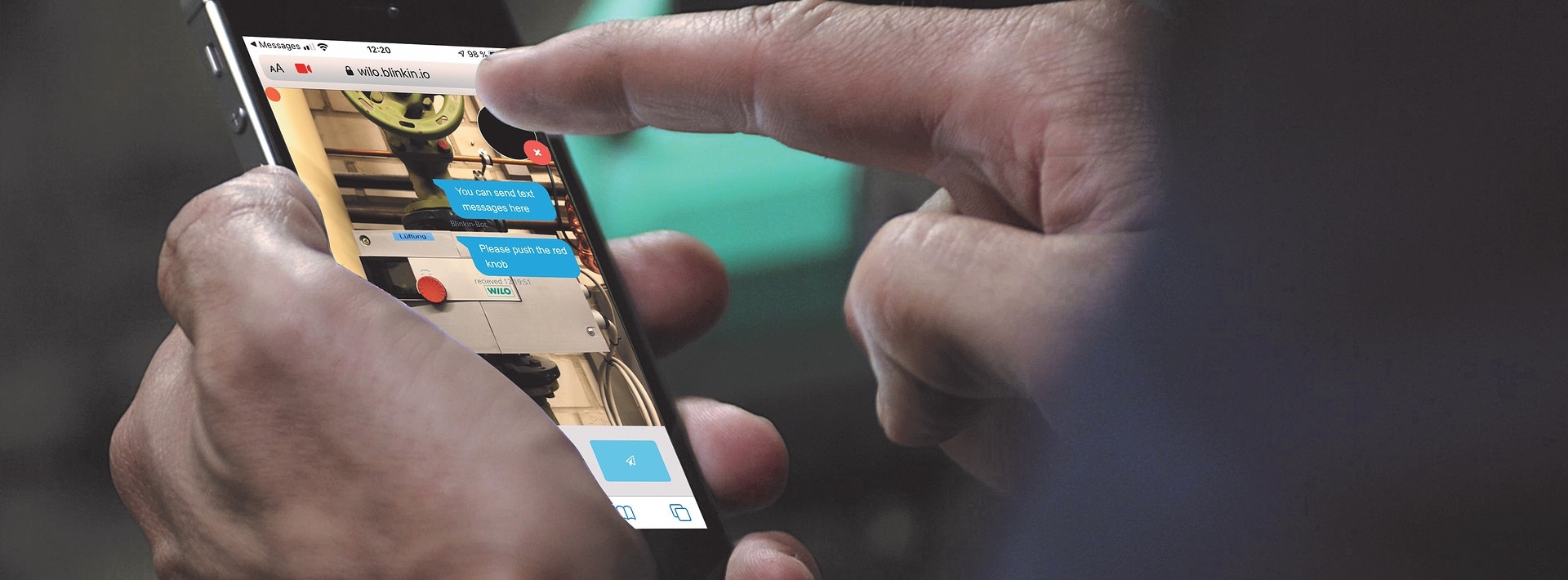

For quick and simple pump replacement for a range of applications including circulation, multistage, borehole, drainage and sewage, visit the Replacement guide.

Whether you’re replacing broken or outdated equipment, you’ll find the most suitable and cost-effective replacement pumps and accessories for your project, along with detailed product and technical information.

Discover Wilo solutions.

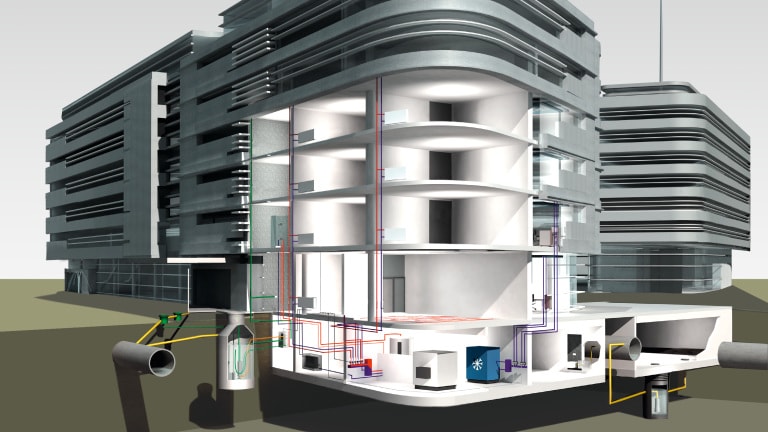

We offer a wide variety of intelligent pumps and systems to make our users’ everyday lives simply more pleasant.

Our energy-efficient solutions are not only ideally suitable for residential, public and commercial properties, but also for water management applications. Wilo products are used in heating, air-conditioning, cooling and water supply applications as well as for drainage and sewage.

Our Sectors

Building Services

Wilo produce a range of pumps and pump systems for both residential and commercial building services. From HVAC to water supply and drainage, Wilo has you covered.

News

8 Apr 2024

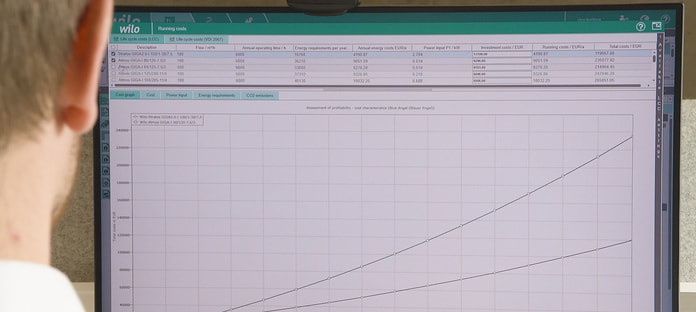

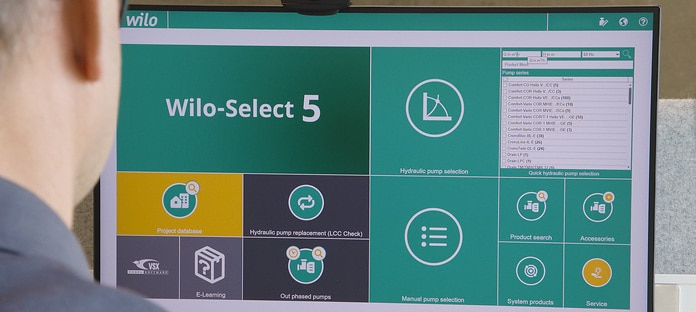

Wilo-Select 5 online – design efficiently and stay on top of things

Always find the right solution for your project

18 Mar 2024

Wilo-Select 5 online – make the right decision quickly and reliably

Reduce design times with optimal pump selection

4 Mar 2024

Wilo-Select 5 online available

All the new features at a glance